Revolutionizing the Hydraulic Industry with Advanced Laser Technology

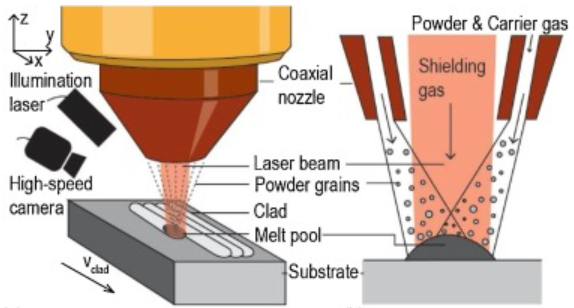

Laser cladding, otherwise known as laser metal deposition, has emerged as an innovative technology with profound implications in the world of hydraulic cylinders. It’s a cutting-edge process that involves the use of a laser beam to deposit material onto a substrate, creating a fully density, corrosion resistant coating or ‘clad’ that can provide enhanced performance attributes compared to conventional coatings.

Understanding Laser Cladding

Laser cladding uses a concentrated laser beam to fuse metal powders to a base material, forming a top layer that boasts superior properties such as improved hardness, durability, and resistance to wear, erosion, and corrosion. The cladding material can vary depending on the desired attributes, but common materials include various types of stainless steel, nickel-based alloys, and cobalt-chromium alloys.

Officially, cladding material is fed into the laser beam’s path in powder form, which melts to form a pool on the substrate. The laser-induced clad layer offers numerous benefits over conventional methods such as thermal spraying—most notably that the bond established between the clad layer and the base material is metallurgical rather than mechanical, resulting in stronger, more durable components that can outperform their traditionally coated counterparts.

What are the methods for repairing hydraulic cylinders?

There are several methods for hydraulic cylinder restoration. Some of these include:

- Disassembly:

This involves taking apart the hydraulic cylinder to examine its components and assess the extent of the damage.

- Inspection & Evaluation:

The disassembled parts are thoroughly inspected to identify the cause of the problem and to evaluate the degree of wear and tear.

- Replacement of Parts & Seals:

Based on the inspection, certain parts and seals that are worn out or damaged will need to be replaced.

- Honing:

This process involves refining the surface of the hydraulic cylinder barrels either manually or using a specialized honing machine.

- Resealing or Complete Overhaul:

In cases where the damage is extensive, it may be necessary to replace all the seals or completely overhaul the hydraulic ram.

- Reassembly:

After the necessary repairs or replacements, the hydraulic cylinder is reassembled carefully, ensuring that all the parts are correctly fitted.

Each method is unique and depends on the specific conditions of the hydraulic cylinder. It’s crucial to choose the most suitable method based on the extent of the damage, the type of hydraulic cylinder, and its application.

Laser Cladding & Hydraulic Cylinders

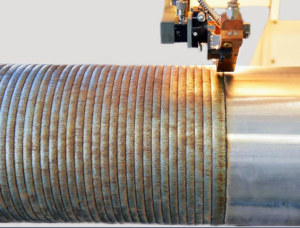

Hydraulic cylinders, which are ubiquitous in heavy machinery, construction equipment, and robotics, are prone to wear and tear due to their constant exposure to harsh operational conditions. Laser cladding has proved instrumental in restoring these hydraulic cylinders back to their original stature—or even better.

Typically, the rod surface of hydraulic cylinders is exposed to various forms of corrosion and abrasion. This can be mitigated by the application of hard chrome plating. But with time, such chrome platings exhibit micro-cracks and eventually peel off, leading to failures. This is where laser cladding comes into play. With its ability to form a strong metallurgical bond with the substrate, and given its exceptional resistance to wear, laser cladding can significantly extend the lifespan of hydraulic cylinders.

What are the advantages of laser cladding hydraulic cylinders compared with traditional coatings?

Laser cladding, also known as laser metal deposition, exhibits superior performance advantages in multiple areas when compared to traditional coating processes. Here are some significant benefits:

Stronger Adhesion:

Traditional coating processes such as flame spray and arc welding usually produce mechanical interlocking between the coating and substrate. However, laser cladding establishes metallurgical bonding, which greatly augments the adhesion and wear resistance of the coating.

Enhanced Wear and Corrosion Resistance:

The material for laser cladding can be selected as per requirement, such as various metal or alloy powders. This allows coatings with specific properties, like excellent wear resistance, anti-corrosion, or high-temperature anti-oxidation, to be procured. This significantly improves the service life of the hydraulic cylinders.

Optimized Heat-Affected Zone (HAZ):

Due to the precise and localized energy input of laser cladding, the resulting heat-affected zone (HAZ) is much smaller when compared to traditional coating processes. This mitigates the degradation of substrate properties and deformation caused by heat input.

Uniformity in Structure and Performance:

The uniformity in coating thickness, microstructure, and performance are much better in laser cladding. This is because the laser cladding process allows for a quick melting and solidification of the powder, leading to a finer and more homogeneous microstructure of the coating. This homogeneity leads to consistent performance across the length of the hydraulic cylinder.

The Future of Laser Cladding in Hydraulic Cylinder Restoration

Looking ahead, the implications of laser cladding for hydraulic cylinders are far-reaching. Its benefits—consistent clad quality, negligible dilution, narrow heat-affected zones, and low substrate deformation—make it an an ideal solution for restoring hydraulic cylinders in heavy-duty machineries in industries like construction, agriculture, and mining.

Moreover, the ability of laser cladding to utilize a wide range of materials means that it can be customized to meet specific performance needs. This opens up new avenues for the manufacture of bespoke hydraulic cylinders that are designed for specialized uses or extreme conditions.

In closing, laser cladding is revolutionizing the way we restore and enhance hydraulic cylinders. Thanks to its superior wear and corrosion resistance, as well as its ability to enhance material properties, this advanced laser technology is set to redefine the industry benchmarks for durability and performance.

How long does it take to repair a hydraulic cylinder?

The time it takes to repair or rebuild a hydraulic cylinder can range from 2-5 days, and sometimes it can even take a full week. It all depends on the extent of damage to the hydraulic cylinder and the complexity of the repair work. For some large hydraulic cylinders, if the damage is serious, it may take 6-8 weeks to repair. Overall, the time it takes to repair a hydraulic cylinder varies based on the specific situation.

How much does it generally cost to repair a hydraulic cylinder with laser cladding?

The cost of repairing a hydraulic cylinder using laser cladding can vary widely based on several factors. These factors include the extent of the damage, the type and size of the cylinder, the specific laser cladding technique used, and labor costs.

Additionally, while the initial cost of laser cladding might seem high compared to other methods, it’s crucial to consider the long-term economic benefits. Laser cladding can achieve more durable, efficient repairs, reduce downtime due to its field-repairable nature, and improve the overall reliability and lifespan of the hydraulic cylinder. Therefore, the cost savings in the long term could potentially outweigh the initial investment.

For specific pricing, it’s best to get a quote from a professional provider of laser cladding services. They would analyze the specific conditions of your hydraulic cylinder and provide a more accurate estimate.

Can you recommend a professional supplier that provides laser cladding repair services for hydraulic cylinders?

Here are some professional suppliers that offer laser cladding repair services for hydraulic cylinders:

- WILA provides professional laser cladding powder and hydraulic cylinder maintenance services. They also offer laser surface strengthening and resurfacing services.

- CB HYMAC are specialists in hydraulic repairs and heavy surface preparation and they can apply a variety of different services such as laser cladding.

- If you’re in Australia, consider WesTrac. Their experienced technicians can solve complex hydraulic circuit problems and provide strong after-sales support for all hydraulic repairs.

- Atelier du Nord’s highly trained team, responsible for restoring hydraulic cylinders, carry out repairs and revisions.

Please note these are some of the suppliers I have found that offer this service, specific services and prices may vary, it is best to contact them directly for more detailed and accurate information.