Parabolic mirrors have been one of the greatest inventions in the field of optical science, proving vital in diverse applications due to their unique property of parallel light focus. This comprehensive article will delve into the fascinating world of parabolic focusing mirrors, exploring their principles, processing methods, applications, and more.

I. Theoretical Foundation: How Parabolic Focusing Mirrors Work?

A parabolic mirror is a reflective surface that possesses a parabolic shape. Consequently, parallel rays of light incident upon this mirror converge at a single point called the focus. This distinctive feature sets parabolic focusing mirrors apart, making them invaluable in various fields.

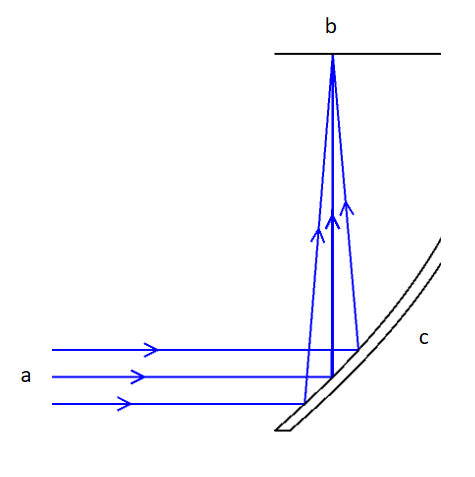

The following is the principle optical path diagram of a parabolic reflector

a is a parallel light incident, illuminates the parabolic reflective surface c, and finally converges to point b. This process is called gathering light path. On the contrary, if light is added to emit from point b, pass through reflective surface c, and reflect to a, a parallel light path output will also be formed. Yes, this process is called collimating the light path, and light is reversible.

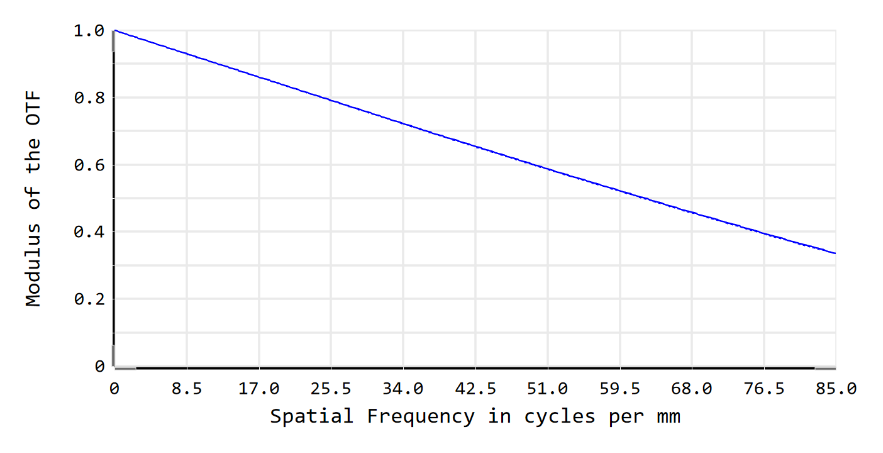

The figure below is the optical transfer function curve graph,

It can be reported that parabolic lenses have very little aberration, so the optical information transmission is relatively high.

II. Processing and Manufacture

The process of manufacturing parabolic focusing mirrors is a meticulous one, calling for precision and state-of-the-art technology. Typically, it involves forming, cutting, grinding, polishing, coating, and final inspection stages to achieve an end product that precisely maintains its parabolic form.

Commonly used parabolic mirror materials include oxygen-free copper, aluminum alloy, etc.

Generally, the reflective surface is coated with gold film, dielectric film, molybdenum plating, etc. The coating is mainly based on the wavelength band of the laser light source.

In the past, the coating band range was 1um, and CO2 gas lasers were mostly used. Recently, fiber semiconductor lasers have been more commonly used, and the coating reflection band is 915-1000nm.

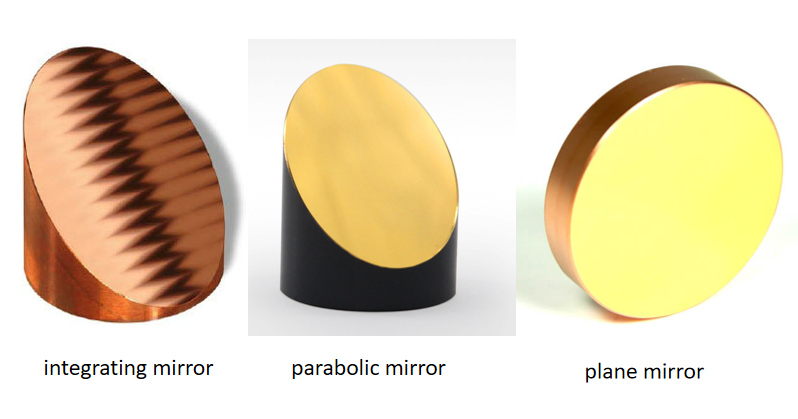

What are the classifications of copper reflectors?

Copper reflectors include plane reflectors, parabolic focusing mirrors, integrating mirrors, freeform mirrors, etc. These classifications provide a general overview but keep in mind that there may be other specific classifications based on the intended use or industry standards.

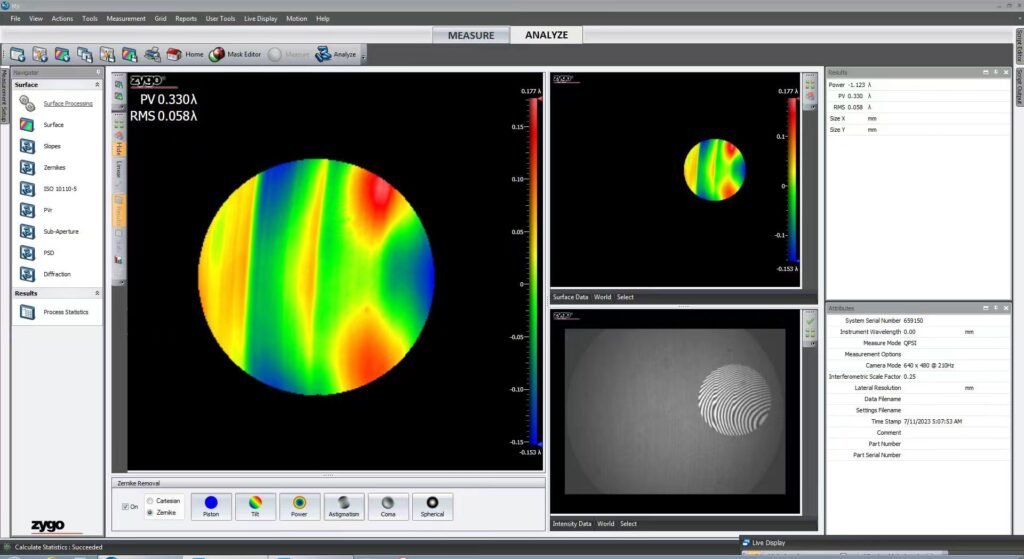

How to check the quality of the parabolic reflector?

Checking the quality of a parabolic reflector is crucial to ensure optimal performance and functionality. Here are several key factors to consider during the quality assessment:

Surface Accuracy:

The reflective surface of a parabolic reflector should have precise curvature and smoothness. Any deviation from the ideal parabolic shape can result in light scattering or defocusing. Use specialized tools like a laser interferometer or a spherometer to analyze the curvature accuracy and identify any irregularities.

Reflectivity:

Evaluate the reflectivity of the mirror’s surface. The higher the reflectivity, the more efficient the mirror will be in focusing light. A quality parabolic reflector should ideally have a high reflectivity coating, such as aluminum or silver, applied uniformly to maximize reflection.

Smoothness:

A smooth surface is essential to minimize scattering and diffraction of light. Inspect the reflector for scratches, pits, or other imperfections that could impact the reflective properties. Use a magnifying glass or microscope to thoroughly examine the surface.

Alignment and Centering:

The parabolic reflector needs to be properly aligned and centered with its supporting structure. Misalignments can cause asymmetrical focusing or distort the reflected image. Check that the reflector is securely mounted and ensure there is no tilt or off-center positioning.

Sturdiness and Durability:

Assess the material quality and construction of the reflector. It should be sturdy, rigid, and durable to withstand environmental factors and maintain its shape over time. Materials like glass, metal, or advanced composites can ensure long-lasting performance.

Image Quality:

Evaluate the quality of the focused image produced by the reflector. Test it by observing objects or patterns at different distances and angles. Look for sharp focus, minimal aberrations, and high resolution.

Application-specific Considerations:

Different applications may have specific requirements for reflector quality. For example, in astronomy, factors such as light-gathering capacity, focal length, and the ability to handle specific wavelengths of light may also need to be considered.

It is recommended to consult experts or professionals in the field of optics and use specialized instruments to conduct a comprehensive assessment of a parabolic reflector’s quality.

III. A World of Applications

Parabolic focusing mirrors are not a recent invention, but their wide range of applications makes them a significant topic in contemporary science.

Scientific Research:

In laboratories, parabolic mirrors are utilized in high-precision devices such as microscopes and telescopes due to their ability to focus incoming light at a single point.

Telecommunications:

Parabolic focusing mirrors, often termed ‘parabolic antennas’, are highly effective in satellite communication systems. They reflect signals from a feed at the antenna’s focus out into space or collect incoming signals for processing.

Solar Energy:

In solar power plants, parabolic mirrors are used to gather and concentrate sunlight onto a small area to produce heat, a technique commonly known as Concentrated Solar Power (CSP).

IV. The Future: High-resolution Imaging and Beyond

While parabolic focusing mirrors have significantly impacted multiple sectors, their potential is far from exhausted. They hold promising opportunities in terms of high-resolution imaging and innovative energy solutions.

Conclusion

Parabolic focusing mirrors continue to form the backbone of numerous optical applications, thanks to their unique focusing capabilities. As research and technology progress in this chameleonic age, one anticipates the emergence of even more sophisticated utilization of these mirrors. A deeper understanding of these tools and their potential applications may indeed open doors to unraveled scientific discoveries and advancements.

Stay Connected

For those interested in more such engaging information or have queries regarding parabolic focusing mirrors, feel free to connect with us. Let’s enlighten each other and navigate through the splendid world of optics together.

Implore Action

For more information on parabolic focusing mirrors, continue exploring our site or contact us. Remember, understanding the role of these mirrors in various technologies helps us appreciate and navigate our modern world more effectively.